Last March I followed a link to the “Trebuchette” project on Kickstarter – “the snap-together, desktop trebuchet”. I hadn’t used Kickstarter before but the Trebuchette project comtained more than enough awesomeness potential and I backed the project. I had a slight disconnect after the project closed funding because I hadn’t really grasped that there would be a non-trivial delay between funding and shipping. However, the frequent, informative posts from the project owners actual gave me a great deal of pleasure to read as they worked through the realities of building a physical-goods business.

The Trebuchette kits arrived right after Thanksgiving. Since Christmas break was right around the corner I decided to put the kits on a shelf and wait until the second week of break when my daughters would be bored out of their skulls. This plan sort of worked – they did ultimately enjoy them, but I made the mistake of telling them what the kit was when I got it and I had to fend off requests to put them together early every couple of days for a month.

BUT! A good day for it finally rolled around and I sat down with Mary (5) and Ellie (3) to put the kit together.

My original project backing level got me two kits. They arrived in one USPS flat-rate mailer. The mailer was very, very damaged when it got to me with at least two of the corners having been ripped open. I was worried about the safety of the kits themselves, but there wasn’t a scratch on them, the packaging worked great.

The quality of the cuts on the pieces is really phenomenal. Every cut is crisp and seemingly perfect. The finish on the wood is protected from scorching by a tape covering that had to be removed. I’m not going to lie here, I think the girls’ favorite part of the build stage was peeling the tape off the pieces. I don’t think this was in the original project plan but at the end of the build they had a ball of tape about the size of a baseball that they threw around for a couple of days.

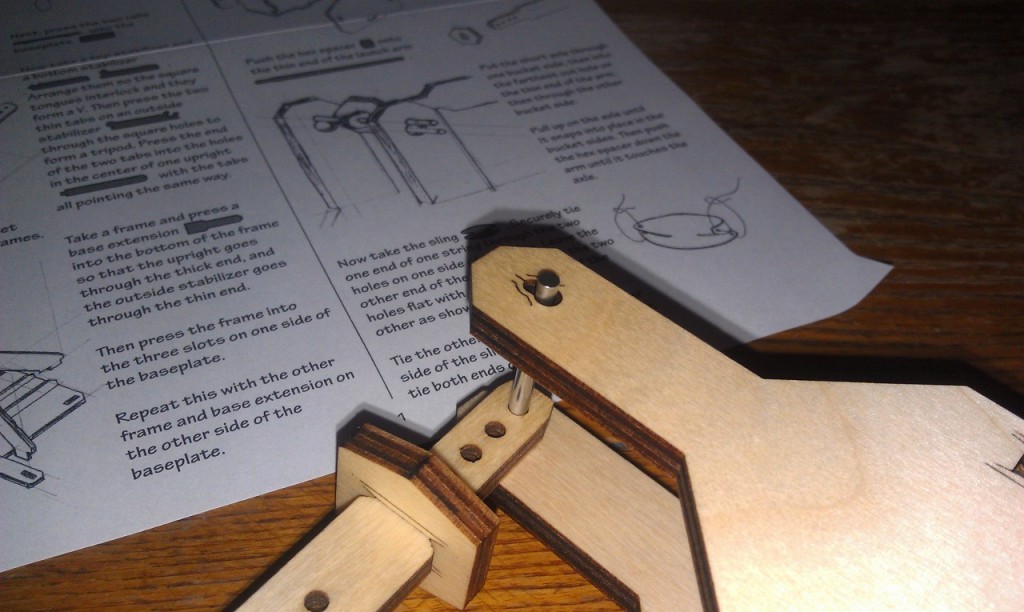

The design of the snap-together joints was, frankly, amazing. By making small “relief” cuts around the sockets the designers nailed the perfect joint – enough “springiness” that you could seat the pieces fairly easily, but enough firmness that there is no wiggle in the assembled piece. In fact, these joints were so easy to put together that there’s not much more to tell about building. I expected the build process to be slightly more difficult with the girls but Mary put almost all of the joints together herself, with a little help with the final seating.

The only really concerning part of the build was connecting the arm to the weight bucket. Even with a bit of relief cut around the socket this was an incredibly firm connection. If I had not had two kits (read: “spare parts”) I probably would have stopped working on it and spent some time googling this step. As it was I pushed through and it did seat, though there was the sound of wood cracking when I seated it. The cracking doesn’t seem to have done anything structural, I can’t see any cracks, but it was a bit disconcerting.

The design of the kit that I was shipped changed some from their original design. They announced these changes ahead of time, but they didn’t mean anything to me. Now that I have played with the kit I definitely appreciate the ones I can see. These changes include how the side-supports connect to the uprights, the stand-offs between the uprights and the main axle, and the joint relief cuts I mentioned above. All of these changes seem well thought out.

My builders really enjoyed making the project, but to be honest I’m still not sure they really understood what it was supposed to be. To the hallway!

Firing it was pretty amazing. The girls loved the mechanism, and it’s incredibly gratifying to fling a rubber ball that far. The experience was marked by an almost constant litany of “watch your head”, but it worked because no one got hurt. By the end Mary was able to load and fire it herself which was pretty awesome. Ellie was able to fire it after being helped to load it. Ellie enjoyed the act of firing it, but Mary was really taken with it as a mechanism. She really enjoyed playing with the release mechanism, the pouch position, and the number of weights to see how it would change how far the ball went.

We did have a slight problem with non-combatants in the line of fire. No cats were hurt in the making of this siege engine

This was a wonderful project to build. The girls loved making and firing it, we killed a cold winter day, and if we ever need to lay waste to a Lego fortress, we have the means.